Patrimoine Days

While the third weekend of September is usually the perfect opportunity to go out and enrich oneself culturally, there's no harm in saying that this time things will be different. Since 2020 has been what it is (some might call it "capricious"), it seems obvious that waiting for hours, packed together in the hope of finally visiting one of Europe's most breathtaking heritage sites, might not be part of your weekend plans.

Given this situation, we thought it best to play it smart. To surprise you and take you somewhere unexpected — where, incidentally, you cannot possibly be. And suddenly, everything becomes as clear as water: if you can't come to our heritage, then it will come to you. Destination: Portugal!

Immerse yourself in our workshops and discover those without whom we would be nothing, or at least very little: our artisans and their masterful hands.

It's not over yet!

A Biche behind the scenes

A few weeks ago, we visited the workshops to discuss prototype compliance, new product launches, and upcoming collections. All in all, a delightful courtesy visit that we love to do.

At that time, our artisans were working on the production of the iconic Lilly Loafer. It’s worth noting that the leather used for these models comes straight from northeastern Italy (Trentino region), and to ensure a breathable shoe, the inner sole is entirely made of lamb leather.

You can imagine how tempting it was to photograph some of their manufacturing steps. So we succumbed, and here’s the result.

KEZAKO

The first assembly

This is simply a piece of leather used during the shoe-making process at the assembly stage. Here, they are stacked and aligned while awaiting to be stitched together with the "tongues" of our shoes.

KEZAKO

The vamp

And here is what the "vamp" of a shoe looks like. This piece, opposite the sole, forms the upper part of the shoe. It is usually made from an assembly of several other pieces that compose the top (the visible part) and the lining (hidden inside the shoe).

In this case, it’s the vamp of our Lilly Leopard Loafers!

Nailing the stitches

Nailing the stitches

Each stitch of our Lilly Leopard Loafers is hammered to flatten the stitch point into the leather’s grain.

KEZAKO

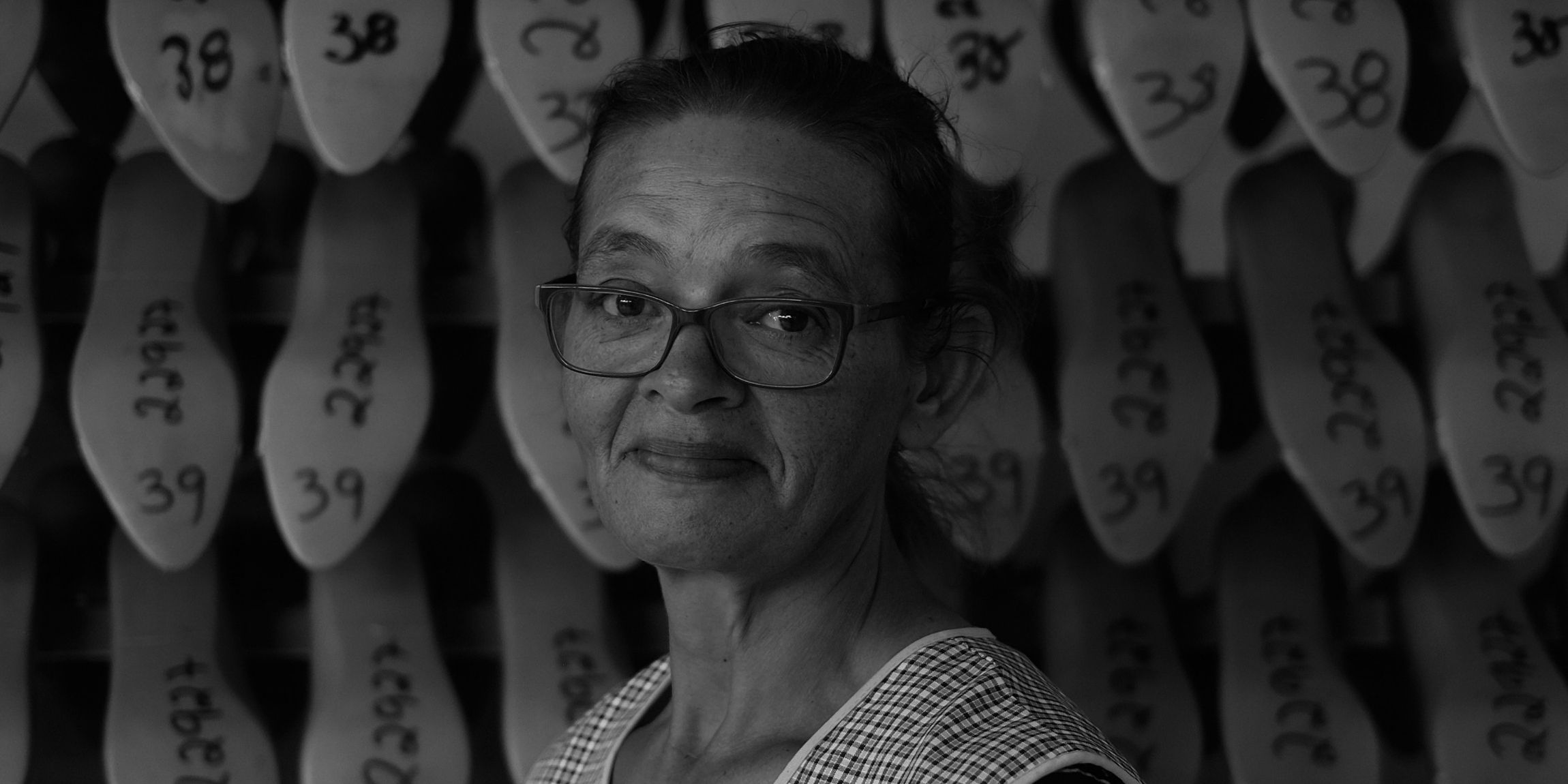

Park of Forms

It's simply the molds used to create shoes in different sizes.

We develop these lasts based on the shape and style we want our shoes to have. This step is crucial because, beyond aesthetics, it directly influences the comfort of the footwear.

For example, the Lilly Loafers feature a slender, elegant shape that remains remarkably comfortable!

KEZAKO

The Assembly Process

Here, the upper parts of our beautiful Lilly Gold Loafers are patiently waiting for the assembly stage, which involves passing through a series of ovens at different temperatures. This process gradually stretches and then firms the leather, allowing it to perfectly mold to the contours of the shape.

Here's a visual demonstration showing not the assembly of the upper, but the back of the Lilly Gold Loafers!

And there you have it—the craftsmanship in action!

And there you have it—the craftsmanship in action!

DISCOVER